10 Easy Facts About Wedge Barriers Shown

Wiki Article

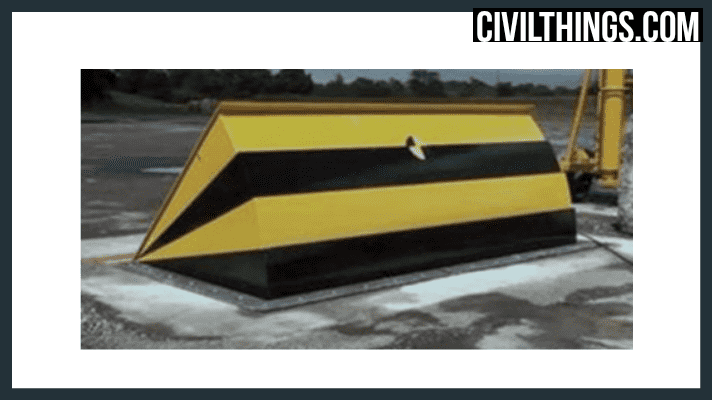

The Ultimate Guide To Wedge Barriers

The spring pole 58 is coupled to a webcam(e. g., cam 80 revealed in FIG. 4) of the training mechanism 50. The springtimes 60 disposed about the springtime rod 58 are kept in compression by spring supports 62, including a fixed spring assistance 64. That is, the set spring support 64 is repaired loved one to the foundation 14 et cetera of the bather 10.

Wedge Barriers for Beginners

The remaining force used to the cam web cam deploy the wedge plate 16 may be provided by an electromechanical actuator 84 or other actuator. The spring setting up 54 and the actuator 84(e. Wedge Barriers. g., electromechanical actuator)might run with each other to equate the camera and lift the wedge plate 16.

As mentioned above, the springtime assembly 54 applies a consistent force on the camera, while the electromechanical actuator may be regulated to exert a variable force on the webcam, consequently making it possible for the training and lowering( i. e., pop over to these guys deploying and retracting )of the wedge plate 16. In specific embodiments, the consistent force applied by the spring assembly 54 may be flexible. g., electromechanical actuator) is disabled. As will certainly be appreciated, the spring setting up 54 might be covered and secured from debris or other elements by a cover plate(e. g., cover plate 68 displayed in FIG. 4) that may be substantially flush with the raised surface 38 of the structure 14. As discussed above, in the released position, the wedge plate 16 serves to block access or traveling past the obstacle 10. The barrier 10(e. g., the wedge plate 16 )might obstruct pedestrians or automobiles from accessing a building or path. As gone over above, the barrier 10 is connected to the support 30 safeguarded within the foundation 14,

front brackets 71. Therefore, the linkage settings up 72 may pivot and rotate to allow the collapse and extension of the link settings up 72 throughout retraction and deployment of the bather 10. The link assemblies 72 cause motion of the wedge plate 16 to be limited. If an automobile is taking a trip towards the released wedge plate 16(e. For instance, in one condition, the safety and security legs 86 might be expanded duringmaintenance of the barrier 10. When the safety legs 86 try this site are released, the safety and security legs 86 sustain the weight of the wedge plate 16 versus the surface 12. Because of this, the lifting system 50 may be shut off, serviced, removed, replaced, and so forth. FIG. 5 is partial perspective sight of a personification of the surface-mounted wedge-style obstacle 10, illustrating the webcam 80 and the webcam surface areas 82 of the training system 50. Specifically, 2 web cam surfaces 82, which are referred to as reduced web cam surfaces 83, are positioned listed below the web cam 80. The reduced camera surfaces 83 might be taken care of to anchor the surface 12 (e. As an example, the lower camera surface areas 83 and the placing plate 85 might form a solitary item that is safeguarded to the support 30 by bolts or various other mechanical bolts. In addition, 2 webcam surface areas 82, which are described as upper web cam surface areas 87, are positioned over the camera 80 and coupled to (e. In various other personifications, stepping in layers or plates may be placed between the surface area 12 and the lower cam surface areas 83 and/or the wedge plate 16 and the upper cam surface areas 87 As discussed over, the webcam 80 converts along the camera surfaces 82 when the wedge plate 16 is lifted from the withdrawed position to the released position. Additionally, as stated over, the springtime setting up 54 (see FIG. 3 )may supply a pressure acting upon the cam 80 in the direction 102 using springtime pole 58, which might decrease the pressure the electromechanical actuator 84 is needed to apply to the webcam 80 in order to actuate and lift the wedge plate 16. 1 )to the deployed placement(see FIG. 4). As revealed, the webcam 80 consists of track wheels 104(e. g., rollers), which contact and equate along the web cam surfaces 82 during operation.

Report this wiki page